Getting your Ford 3000/3400 tractor started shouldn't be a battle. A common culprit behind starting issues is a faulty starter solenoid, often complicated by wiring problems or poor grounding. This guide provides a step-by-step solution, regardless of your mechanical experience level. Let's get your tractor running smoothly again! For additional Ford tractor resources, check out Yesterday's Tractors.

Safety First: Essential Precautions

Before starting any electrical work, always disconnect the negative (-) terminal from your tractor's battery. This prevents dangerous electric shocks and short circuits—a critical step that should never be skipped. Remember, safety is paramount. Consider also wearing safety glasses and gloves.

Tools and Materials: What You'll Need

You won't need a professional workshop, but having the right tools makes the job easier and safer. Here's what you'll need:

- Multimeter (to test electrical circuits)

- Phillips and flathead screwdrivers (various sizes may be needed)

- Wrenches (sizes will depend on your tractor's specific solenoid)

- Wire brush (to clean corroded terminals)

- Electrical tape (for insulating repaired connections)

- Replacement solenoid (highly recommended to have on hand)

- Wire strippers/crimpers (if repairing wires)

Troubleshooting: Pinpointing the Problem

Let's systematically find the root cause of your starting issue. This process is like detective work, examining the clues systematically.

1. Visual Inspection: A Careful Examination

Begin with a thorough visual inspection of the solenoid, its wiring, and all connections. Look for:

- Corrosion: Green, crusty buildup on terminals significantly hinders electrical conductivity. Clean them thoroughly with a wire brush.

- Loose Connections: Loose or poorly connected wires are a major source of starting problems. Tighten all connections securely.

- Damaged Wires: Check for fraying, breaks, or melted insulation. Replace any damaged sections of wiring.

- Solenoid Damage: Inspect the solenoid itself. Is it loose? Does it show signs of burning or damage? A loose mount can disrupt the electrical connection.

2. Testing the Solenoid: Using a Multimeter

Your multimeter is key here. Refer to online resources for detailed instructions on testing a solenoid's continuity and coil resistance. This will help determine if the solenoid itself is faulty. Did you know that a multimeter can quickly reveal a defective component by measuring electrical resistance?

3. Wiring Check: Following the Electrical Path

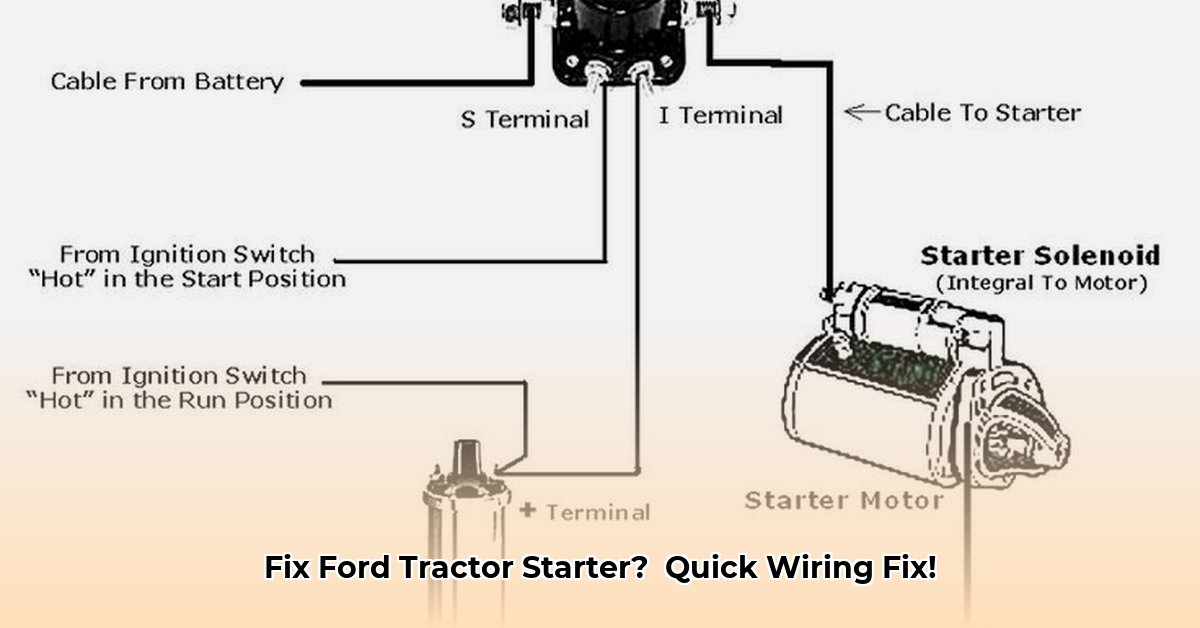

Use a reliable Ford tractor starter solenoid wiring diagram specific to your tractor's year and model. Wiring diagrams vary, even between models within the 3000/3400 series. Compare your tractor's wiring to the diagram, noting any discrepancies. This is crucial for identifying broken circuits and short circuits. A carefully traced wiring path often reveals hidden problems.

4. Grounding Verification: Ensuring a Solid Connection

A poor ground connection can prevent the starter from receiving sufficient current. Verify that the engine block and the solenoid's mounting point have clean, secure ground connections. A secondary ground wire can improve conductivity and reliability. Neglecting grounds is a common oversight.

Repair Procedures: Fixing the Problem

Once you've diagnosed the problem, it's time for repairs.

- Solenoid Replacement: If the solenoid is faulty, carefully remove and replace it, ensuring a secure fit and tightening all mounting bolts—avoid over-tightening!

- Wire Repair: For damaged wires, carefully splice in new wire using appropriate connectors and insulate the connections with electrical tape. Ensure a watertight seal if exposed to elements.

- Ground Improvement: Clean all grounding points with a wire brush and tighten connections. Consider adding a secondary ground wire for enhanced reliability.

Verification and Testing: Does It Start?

After making repairs, reconnect the battery's negative terminal. Attempt to start the tractor. If it starts immediately, congratulations! If not, carefully review your troubleshooting steps and double-check your work.

Conclusion: Getting Back to Work

By following these steps, you can effectively diagnose and repair starting problems in your Ford 3000/3400 tractor. Remember, careful observation, methodical testing, and accurate repairs are key to success. Don't rush the process. A bit of patience goes a long way with tractor repair.

Additional Resources: Further Assistance

Online forums dedicated to Ford tractors (like Yesterday's Tractors) are invaluable resources for troubleshooting and repair tips. Consulting your tractor's owner's manual might also provide additional relevant information.